F7A4-EH14

F7A2-EM12

F7AO-EA2-A2

Semi-alkaline sintered flux, used in conjunction with appropriate submerged arc welding wire (such as EH14, EA2, EM12K, etc.), is used for welding important structural steel. The weld hardly adds Si and Mn, and is metallurgically neutral. It has excellent welding process performance, stable arc, good surface quality, good slag removal performance, and high low-temperature impact toughness. When welding filler metal with direct current, the positive electrode should be connected. can be used in many fields such as boilers, pressure vessels, pipelines and low-alloy steel structures.

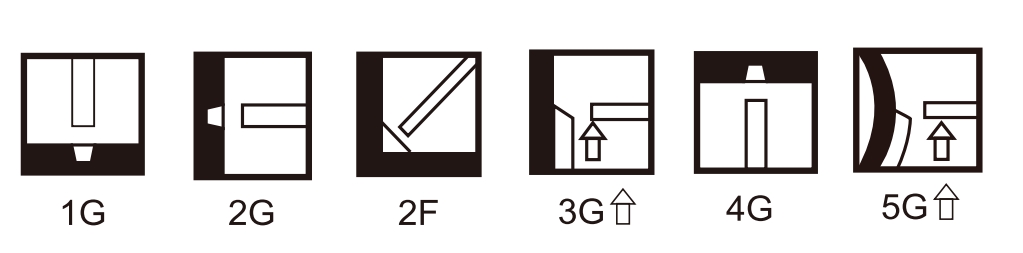

Welding Position

Flux type: fluoride alkali

Basicity index: 1.80

Particle size: 2.0-0.28mm (10-60 mesh)

SiOz+TiO₂ | CaO+MgO | Al₂O₃+Mn0 | CaF₂ | S | P |

15-25 | 25-35 | 20-30 | 15-25 | ≤0.035 | ≤0.04 |

Wire matched | Yield Stress

| Tensile Strength

| Elongatio | AKV(J) | ||

0℃ | -20℃ | 40℃ | ||||

SU34 | ≥390 | 490-670 | ≥18 | ≥110 | ≥80 | ≥47 |

EH14 | ≥400 | 490-670 | ≥18 | ≥47 | ||

1. The flux must be baked at 300-350℃ for 2h before use.

2. Before welding, remove rust, oil, moisture and other impurities on the weldment.

Request Your Free WOERDE Welding Wire Sample

Experience WOERDE’s superior welding wires firsthand. Fill out our online form to request a free sample today. Discover why global businesses trust WOERDE.