ER110S-G - Gas-Shielded Welding Wire

Suitable for welding high strength structures with tensile strength of 790MPa.It can be used for welding some key structures,such as pressure vessels,construction machinery, hoisting machinery,ships,mining machinery,etc.

What is ER110S-G

is a kind of high strength gas-shielded welding wire.The mixed gas Ar+20%CO2 can be used as shielding gas.It has soft arc,stable burning and fewer spatters.The bead has higher impact toughness.

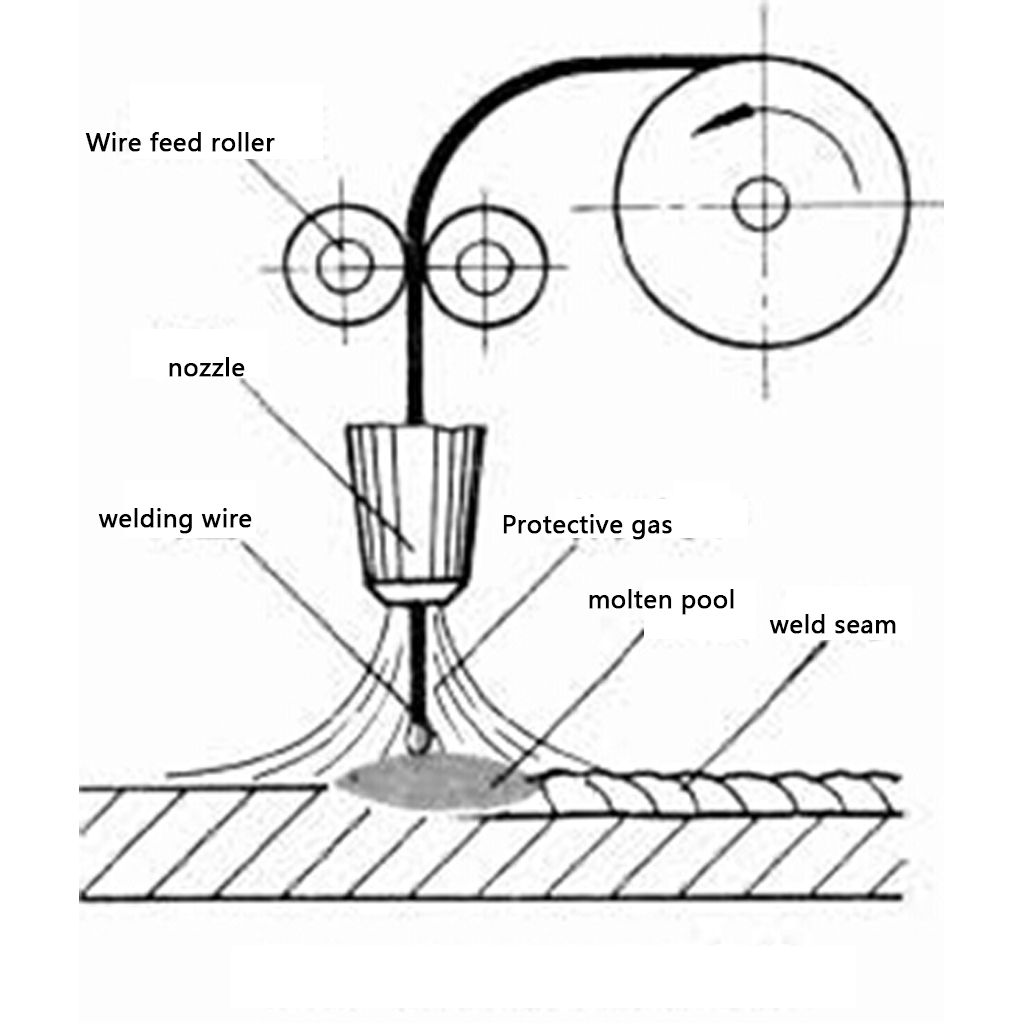

How CO2 gas shielded welding wire Works

During the welding process, the CO2 gas shielded welding wire is fed through the welding gun and meets the arc to form a molten pool. An external shielding gas (usually a mixture of argon and carbon dioxide) is simultaneously released to protect the weld pool from atmospheric contamination. This ensures clean, high-quality welds. The compatibility of gas shielded welding wire with various shielding gases and its stable performance make it the first choice for many industrial applications.

Gas shielded welding wire is a welding material used for gas shielded welding. Its product structure mainly includes the analysis of the following aspects:

Welding wire material: The main components of gas shielded welding wire usually include metal alloys, such as steel, aluminum, copper, etc. The material of the welding wire directly affects the performance and scope of application of welding.

Coating agent: The surface of the welding wire is usually covered with a layer of coating agent. This is to provide a protective atmosphere during the welding process and prevent the adverse effects of oxygen, moisture, etc. on the welding. The composition and performance of the coating agent affect the quality and stability of the welding.

Diameter and specifications: The diameter and specifications of the gas shielded welding wire are determined according to the specific welding needs. Different welding tasks may require different diameters and specifications of welding wire. This also affects the welding current parameters and the width of the weld.

Strength and hardness: The welded joint needs to have a certain strength and hardness to ensure the durability and stability of the weld. The material of the welding wire and heat treatment and other processes will affect these properties after welding.

Weldability: The weldability of gas shielded welding wire refers to the operability during the welding process, including good arc stability, less spatter and other characteristics. This has an important impact on the control of the welding process and the convenience of welding operations.

Comprehensive analysis of the above aspects can help formulate a gas shielded welding wire selection plan suitable for specific welding tasks to ensure welding quality and effect.

Typica | l Chemical Composition of welding wire(%) | |||||

C | Mn | Si | P | S | Cu | other |

0.074 |

1.75 |

0.47 |

0.008 |

0.004 |

0.20 | Cr:0.30 Ni:2.11 Mo:0.54 |

Typical Mechanical Properties of The Deposited Metal(100%CO2) | ||

Yield Strength Tensile Strength Elongation ReL/Rpo.2 (Mpa) Rm(Mpa δs(%) | Impact test | |

Temperature (℃) | Impact Energy KV2(J | |

730 840 24 | -20℃ 90 | |

Packing terms | |||||||

Diameter | 0.6mm | 0.8mm | 0.9mm | 1.0mm | 1.2mm | 1.6mm | 2.0mm |

Plastic spool 1kg D100mm | √ | √ | √ |

| √ |

|

|

Plastic spool 5kg D200mm | √ | √ | √ | √ | √ | √ |

|

Plastic spool 15kg D270mm | √ | √ | √ | √ | √ | √ | V |

Metal basket 15kg K300mm | √ | √ | √ |

| √ |

| √ |

Drum packing 100kg |

| √ | √ |

|

|

|

|

Drum packing 250kg/350kg |

| √ | √ |

| √ | √ | √ |

Packing terms | ||||||

Diameter | 1.2mm | 1.6mm | 2.0mm | 2.4mm | 3.2mm | 4.0mm |

TIG/1000mm x 5kg/tube | √ | √ | √ | √ |

|

|

TIG/1000mmx10kg/tube | √ | √ | √ | √ | √ | |

CO2 gas-shielded welding wires, commonly used in the Gas Metal Arc Welding (GMAW) process, have a broad range of applications across different industries. Some key industries where CO2 gas-shielded welding wires are frequently utilized include:

Automotive Industry:

- Applications: Welding of automotive components, such as frames, chassis, exhaust systems, and body panels.

Construction Industry:

- Applications: Welding for the fabrication of structural steel components, beams, and other construction materials.

Shipbuilding Industry:

- Applications: Welding of ship structures, including the assembly and repair of various marine vessels using CO2 gas as a shielding agent.

Oil and Gas Industry:

- Applications: Welding for pipelines, storage tanks, and other equipment used in the exploration, production, and transportation of oil and gas.

Heavy Equipment Manufacturing:

- Applications: Welding for the fabrication of heavy machinery and equipment used in industries like mining, agriculture, and earthmoving.

Railroad Industry:

- Applications: Welding for the manufacturing and repair of railroad components, including tracks and rolling stock.

Infrastructure and Bridge Construction:

- Applications: Welding for the construction and maintenance of infrastructure projects, including bridges, tunnels, and highways.

Energy Sector:

- Applications: Welding for power generation facilities, including the construction and maintenance of power plants and renewable energy infrastructure.

General Manufacturing and Fabrication:

- Applications: Versatile use in general metal fabrication for a wide range of applications across different industries.

Mining Industry:

- Applications: Welding for the fabrication and repair of mining equipment and structures.

Agricultural Machinery Manufacturing:

- Applications: Welding for the production of agricultural machinery and equipment.

Metal Furniture Manufacturing:

- Applications: Welding for the fabrication of metal furniture, cabinets, and fixtures.

Appliance Manufacturing:

- Applications: Welding for the production of appliances such as refrigerators, washing machines, and ovens.

Structural Steel Fabrication:

- Applications: Welding for the fabrication of structural steel components used in various construction projects.

Automated Welding Systems:

- Applications: CO2 gas-shielded welding wires are compatible with automated welding systems, contributing to increased efficiency in manufacturing processes.

The production of CO2 gas-shielded welding wire should adhere to relevant welding and manufacturing standards to ensure quality, safety, and performance. While specific standards may vary based on regional and industry requirements, several key standards are commonly referenced for the production of welding consumables, including CO2 gas-shielded welding wires. Here are some important standards:

AWS A5.X – Specification for Filler Metals:

AWS A5.X series includes various specifications for filler metals, and the specific standard for CO2 gas-shielded welding wire would depend on the type of material being used. For example, AWS A5.18 covers carbon steel electrodes for gas shielded arc welding.

AWS D1.1/D1.1M – Structural Welding Code – Steel:

If the CO2 gas-shielded welding wire is intended for structural steel applications, compliance with AWS D1.1/D1.1M ensures that the welding wire meets the structural welding requirements for steel.

AWS QC3 – Standard for AWS Certification of Robotic Arc Welding Personnel:

If the production involves the use of robotic welding systems, compliance with AWS QC3 ensures that personnel involved in robotic arc welding are certified and qualified.

ISO 14341 – Welding consumables – Wire electrodes and weld deposits for gas shielded metal arc welding of non-alloy and fine-grain steels – Classification:

This ISO standard provides classification requirements for wire electrodes used in gas-shielded metal arc welding of non-alloy and fine-grain steels.

ISO 9001 – Quality Management Systems:

Compliance with ISO 9001 ensures that the production process follows international standards for quality management, covering aspects such as process control, traceability, and continuous improvement.

ISO 14001 – Environmental Management Systems:

For environmentally conscious production, compliance with ISO 14001 ensures adherence to environmental management standards, covering aspects such as waste management and resource efficiency.

ISO 3834 – Quality requirements for fusion welding of metallic materials:

This standard specifies quality requirements for welding processes and is applicable to the entire welding fabrication process, ensuring the quality of the welding operation.

EN ISO 14171 – Welding consumables – Solid wire electrodes, tubular cored electrodes and electrode/flux combinations for submerged arc welding of non-alloy and fine-grain steels – Classification:

If the production involves welding wires for submerged arc welding, this European standard provides classification requirements.

Request Your Free WOERDE Welding Wire Sample

Experience WOERDE’s superior welding wires firsthand. Fill out our online form to request a free sample today. Discover why global businesses trust WOERDE.