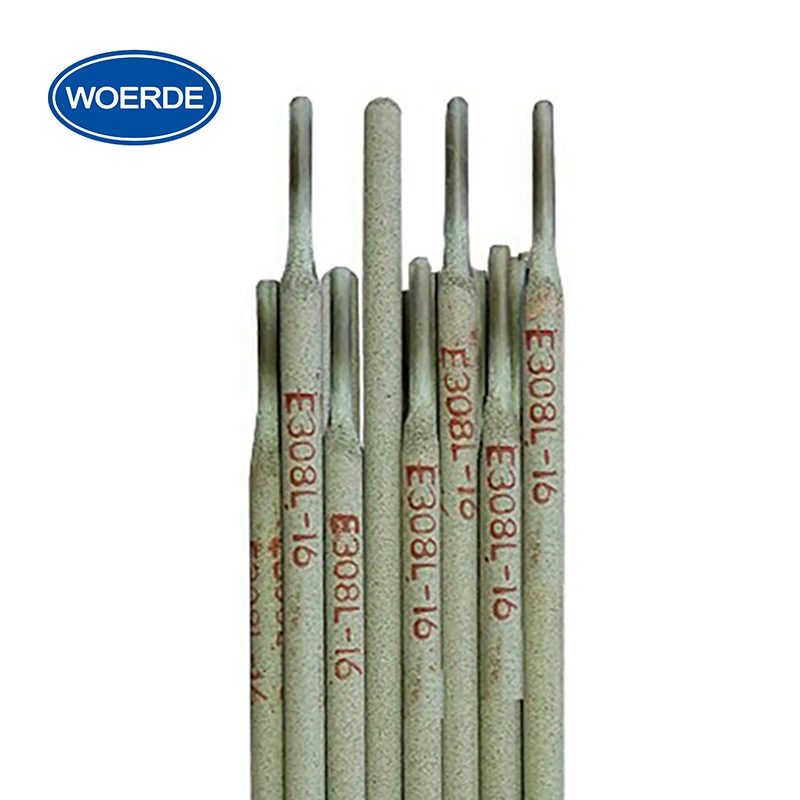

Welding Electrode

WOERDE is an industrial welding consumables manufacturer that offers a comprehensive range of welding products. Our manufacturing facility in China produces high-quality Welding Electrodes for demanding industrial applications.

WOERDE also supplies various types of welding consumables, including solid copper, flux-cored, stainless steel, aluminum, and copper welding wires, as well as electrodes. The Welding Electrode is a crucial component in many welding processes, often used in construction, automotive, shipbuilding, and other heavy industries.

Welding Electrodes belong to the family of arc welding consumables. They are used to conduct current through a workpiece to fuse two pieces together. Depending on the process, the Welding Electrode will either be consumed in the weld or reused. The advantages of WOERDE’s Welding Electrodes include: robust construction, consistent performance, and adaptability to various welding techniques.

All You Need To Know About Welding Electrode

Welding Electrode is a type of welding consumable that conducts current through the workpiece, creating the heat needed to fuse materials together. The design makes this electrode suitable for various welding processes, including Manual Metal Arc Welding (MMAW) and Tungsten Inert Gas Welding (TIG). For many industrial applications, Welding Electrode is used for its consistent performance and adaptability.

Because this type of welding consumable offers excellent electrical conductivity and is available in various materials and coatings, industries that require welding operations use them very often. Additionally, many industries prefer Welding Electrode as it is versatile, suitable for different materials, and requires proper handling and storage. Welding Electrode can be used in various welding processes, including Stick Welding (SMAW) and Gas Tungsten Arc Welding (GTAW).

This article provides you with everything you need to know about Welding Electrode. What you’ll learn includes the uses of Welding Electrode, its composition, the mechanism behind how it works, and the different types of Welding Electrode. In the later end, you can check the difference between Welding Electrode and other types of welding consumables, understanding why it’s a preferred choice for many welding applications.

How Does Welding Electrode Work?

Welding Electrode primarily acts as a conductor in welding operations. The electrode is held in a welding clamp and is brought close to the workpiece; an electric arc is established between the electrode and the workpiece.

The diameter of this electrode is typically matched to the thickness of the materials being welded. When the welding operation starts, the tip of the electrode melts, creating a weld pool that combines with the base metal to form the weld. Depending on the type of welding, a shielding gas or flux coating on the electrode may be used to protect the weld pool from atmospheric contamination. The welding process continues with the electrode being continuously fed (in some processes) or replaced as it is consumed.

What Are Welding Electrodes Used For?

Welding Electrodes are used in a wide range of industries that require welding operations. These could be the following

- Automotive Manufacturing

- Shipbuilding Industry

- Construction Industry

- Aerospace Industry

- Pipeline Fabrication

- Heavy Equipment Manufacturing

- Railroad Construction

- Oil and Gas Industry

- Power Generation

- Metal Fabrication

Considerations When Buying Welding Electrode

Making the Right Choice for Your Welding Needs

01.

Type of Material to be Welded

Different electrodes are designed for welding various materials such as steel, stainless steel, aluminum, etc. Selecting the right electrode for the material ensures strong and durable welds.

02.

Welding Process Compatibility

Welding electrodes are designed to be used with specific welding processes like MIG, TIG, Stick, etc. Understanding the compatibility with your welding process is essential for achieving the desired weld quality.

03.

Coating and Flux Composition

The coating or flux composition of the electrode affects the stability of the arc, slag formation, and other welding characteristics. Choosing the right coating ensures smoother welding and better final results.

04.

Storage and Handling Requirements

Welding electrodes require proper storage and handling to maintain their quality. Consider the manufacturer's recommendations for storage temperature, humidity control, and packaging to prevent contamination or degradation.

Benefits of Using Welding Electrode

Enhancing Welding Performance Across Various Applications

Versatility

Welding electrodes are available in various types and compositions, making them suitable for welding a wide range of metals and alloys across different industries.

Ease of Use

With proper selection and handling, welding electrodes offer ease of use, even for less experienced welders. They can be used in different positions and welding processes.

Enhanced Safety

Quality welding electrodes contribute to a safer welding environment by reducing spatter, fumes, and other potential hazards when used according to guidelines.

Improved Weld Quality

The right welding electrode can significantly enhance the quality of the weld, providing strong, durable, and defect-free joints that meet industry standards.

Cost-Effectiveness

Welding electrodes are available in different price ranges, allowing for cost-effective solutions without compromising on quality. Bulk purchasing options can further reduce costs.

Environmental Considerations

Many welding electrodes are designed with eco-friendly materials and coatings, aligning with environmental regulations and sustainability goals.

Technical Specifications of Welding Electrode

A Comprehensive Guide to Selecting the Right Welding Electrode for Your Needs Below is a table that outlines the key technical specifications that customers often consider when selecting a welding electrode. These specifications can vary widely depending on the type of metal being welded, the welding process used, and other factors.

| Specification | Description | Common Variants |

|---|---|---|

| Type | Refers to the classification of the electrode based on the coating and core wire material. | E6010, E7018, E308L, etc. |

| Material | The core material used in the electrode, often matching or complementing the base metal. | Carbon Steel, Stainless Steel, Aluminum |

| Coating | The material coating the core, affecting the stability of the arc and slag formation. | Rutile, Basic, Cellulosic |

| Diameter | The thickness of the electrode, affecting the penetration and deposition rate. | 1/16″, 3/32″, 1/8″, 5/32″ |

| Length | The length of the electrode, influencing the handling and reach in welding. | 12″, 14″, 18″ |

| Current Type | The type of electrical current suitable for the electrode, either AC, DC, or both. | AC, DC, AC/DC |

| Tensile Strength | The minimum tensile strength the weld deposit is expected to meet, measured in ksi. | 60 ksi, 70 ksi, 80 ksi |

| Position | The positions in which the electrode can be used (e.g., flat, horizontal, vertical, overhead). | All-position, Flat & Horizontal |

| Polarity | The electrical polarity required for the electrode. | DCEP, DCEN, AC |

Understanding these specifications is essential for selecting the right welding electrode for your specific application. Always consult with a welding professional or supplier to ensure the best choice, and refer to the manufacturer’s guidelines for detailed information on each specification.

Safety and Handling Instructions for Welding Electrodes

Essential Guidelines for Safe and Effective Use of Welding Electrodes

01.

Proper Electrode Selection

Choose the right type of electrode for the specific welding process and base metal. Incorrect selection can lead to weak welds and potential failure.

02.

Correct Amperage Setting

Set the welding machine to the appropriate amperage for the electrode being used. Too high or too low amperage can cause various welding defects.

03.

Storage of Welding Electrodes

Store electrodes in a clean, dry area. Moisture exposure can damage the electrodes, leading to hydrogen-induced cracking. For electrodes in use, follow the manufacturer's guidelines for proper storage.

04.

Safety Equipment

Always use appropriate safety gear, including welding helmets, gloves, and protective clothing. Ensure your work area is well-ventilated to prevent the accumulation of potentially harmful fumes.

05.

Electrode Handling

Handle the electrodes with care, avoiding any damage to the coating. Damaged coatings can lead to unstable arcs and contaminated welds.

06.

Training and Certification

As with any welding process, proper training is essential. If you're new to using Welding Electrodes, consider seeking additional training or certifications to ensure mastery of the process.

Remember, safety should always be your top priority when working with Welding Electrodes. Always follow manufacturer guidelines and industry best practices to ensure a safe and productive work environment. By adhering to these guidelines, you can achieve consistent weld quality and minimize potential risks.

Request Your Free WOERDE Welding Wire Sample

Experience WOERDE’s superior welding wires firsthand. Fill out our online form to request a free sample today. Discover why global businesses trust WOERDE.